Commercial algaecide effective at removing cyanobacterium Planktothrix sp.

Most fish farmers operating in freshwater ponds will at some point encounter blooms of nuisance microalgae, which threaten the health and quality of their aquacultured products. Of particular concern are cyanobacteria because they produce toxins, as well as compounds (e.g., geosmin and 2-methyl isoborneol) that cause off-flavors in fish.

The main toxins are microcystins that can accumulate in the fish flesh, which poses safety concerns because these can be passed to human consumers. Preventive methods are perhaps the best management option, such as maintaining low nutrient levels – particularly phosphorus (P) – through water exchanges and/or the use of P-binding clay. However, some farmers observe that elevated temperatures often trigger nuisance microalgae blooms.

Off-flavors from nuisance microalgae cause serious economic losses to farmers due to the cost and delay involved to purge the fish prior to harvesting and/or strategies to remove cyanobacteria. Therefore, some farmers use algaecides, such as copper sulfate or alum. However, these tend to be less selective and can also cause toxicity to other beneficial microalgae and zooplankton.

The sudden die-off of the primary producers, including nuisance microalgae, can cause three problems. Firstly, without the main organisms to remove dissolved nitrogen, the ammonia and nitrite levels can subsequently spike. Secondly, the dead microalgae would contribute to increased biological oxygen demand that could strip oxygen out of the water. Thirdly, large amounts of microcystins would be released as the cyanobacteria die and are then taken up by animals.

A more selective compound to kill cyanobacteria includes using hydrogen peroxide (H2O2). Traditionally, this is added in liquid form but can pose safety concerns due to accidental spilling during transport, storage and application. Other H2O2-based products have emerged in the form of sodium carbonate peroxyhydrate (SCP) that, when added to water, is rapidly converted to H2O2 and sodium carbonate. Therefore, this is more stable, but largely untested in an aquaculture context.

In this article – adapted and summarized from the original publication (Science of the Total Environment (DOI:10.1016/j.scitotenv.2018.05.023) – we summarize results of a study to test a novel SCP-based product within small- and large-scale hypereutrophic tanks and ponds, respectively, that were both dominated with cyanobacteria. The small-scale trial was first conducted to narrow down the most appropriate doses to kill cyanobacteria without potentially harming beneficial microalgae and zooplankton. Based on these results, two optimal doses (2.5 and 4.0 mg/l H2O2) were tested within commercial ponds (large-scale trial) and over six weeks the cyanobacterial abundance, plankton abundance, microcystins and persistence of H2O2 levels were monitored.

Experimental design

Nutrients (inorganic fertilizer and de-oiled rice bran) were added, as needed, to pond water until hypereutrophic, cyanobacteria-dominated conditions were obtained (first image at the top). Identical nitrogen to total P conditions were used and the dominant cyanobacterium was Planktothrix sp.

In both trials, a granular SCP based algaecide (PAK® 27) was used, which is a USEPA-approved compound (SePRO Corporation, Carmel, IN, U.S.A.). Different dosages of H2O2 were prepared by dissolving the algaecide (active ingredient ~ 27 percent H2O2) granules in moderately hard water (~ 187 mg/l as CaCO3) analogous to local water conditions.

Small-scale trial

Three circular, 75-L barrels were installed in each of the six hypereutrophic ponds and filled with this water. The algaecide was added at 0, 5.56, 7.41, 9.26, 11.11, 12.96, 14.81, 18.52 and 29.63 mg/L to achieve final concentrations of 0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 5.0 and 8.0 mg/L H2O2, respectively. Samples were daily taken between 10:00 and 12:00 over 10 days to monitor changes in cyanobacteria, eukaryotic microalgae and zooplankton abundance. Dissolved oxygen (DO), conductivity (µS/cm), pH and water temperature (degrees-C) were measured using a digital probe. Turbidity was measured using a Secchi disk and total phosphorus, ammonia nitrogen, nitrite-N, nitrate-N, total alkalinity and total hardness using commercial kits.

The average concentration of Planktothrix sp. prior to the algaecide applications was 1.08 × 106 cells/mL, while the combined taxa of various microalgae were 5.24 × 104 cells/mL. Among the tested concentrations, 2.5 mg/L H2O2 was the lowest dose that significantly reduced Planktothrix sp., and higher concentrations led to no further significant improvement at reducing cyanobacteria. At 4.0 mg/L H2O2 there was also no adverse effect to the plankton. However, concentrations of ≥ 4.0 mg/L adversely impacted the abundance of the non-targeted plankton community that included Synedra, Spirogyra and Cladophora sp. Therefore, 2.5 and 4.0 mg/L H2O2 were selected for testing in the large-scale trial.

Large-scale trial

A total of four ponds were randomly selected for the two H2O2 treatments, while the remaining two ponds were used as reference (control) ponds. Paddlewheels were used to facilitate an even dispersal of the algaecide. Similarly, as in the small-scale trial, the cyanobacterial / plankton abundance and water quality were measured along with assessing microcystins, chlorophyll-a and persistence of H2O2 over six weeks.

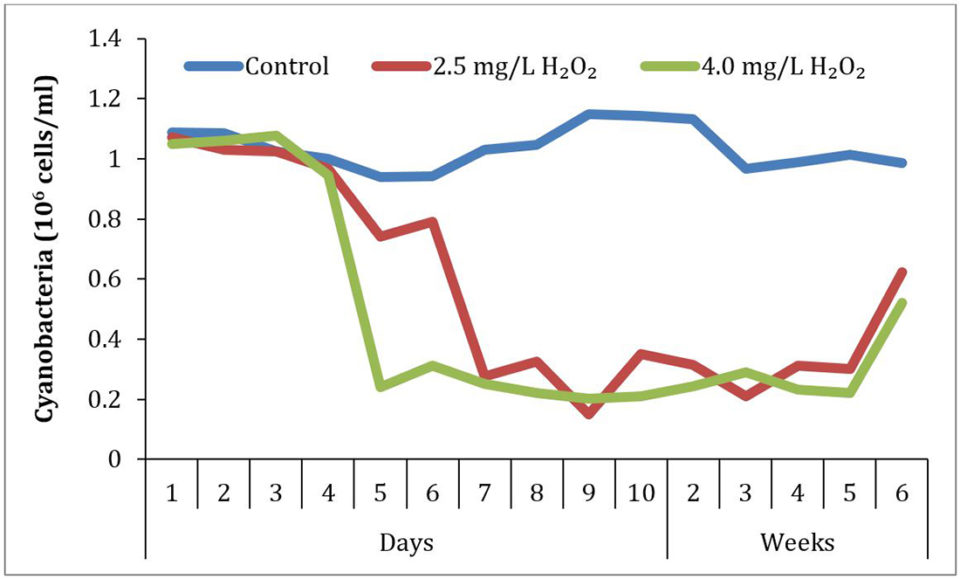

Both doses of 2.5 and 4.0 mg/L H2O2 significantly decreased Planktothrix sp. concentrations, but at different times of seven and five days post-application, respectively (Fig. 1). There was also a notable change in the appearance of the water after three days, where the cyanobacteria were dying and the water appeared to have a more greenish-brown coloration. A gradual recovery of Planktothrix sp. populations became apparent between weeks 5 and 6, although abundances were still far less than both the control or during the pre-application phase. In the 2.5 mg/L H2O2 treatment, the cyanobacterial decrease coincided with increased eukaryotic phytoplankton, particularly diatoms and green algae. Moreover, herbivorous zooplankton that included Brachionus sp., Daphnia sp., and calanoid and cyclopoid copepods were unaffected. In contrast, 4.0 mg/L H2O2 suppressed these phyto- and zooplankton, which was in contrast to the small-scale trial.

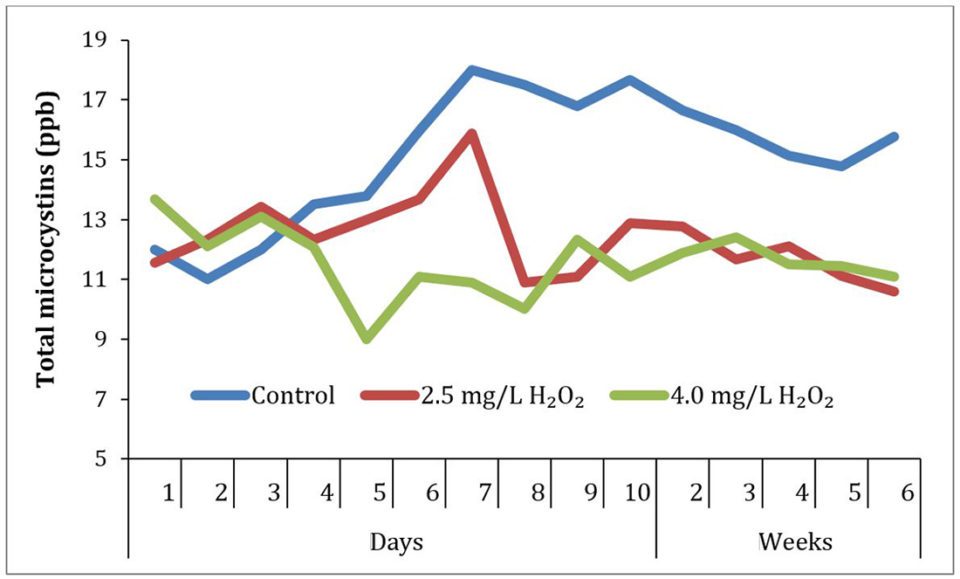

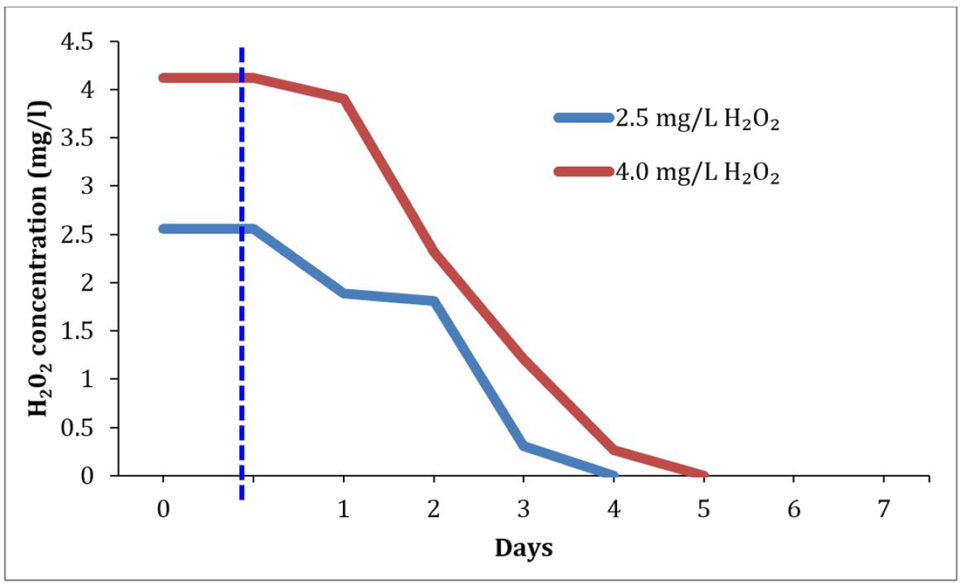

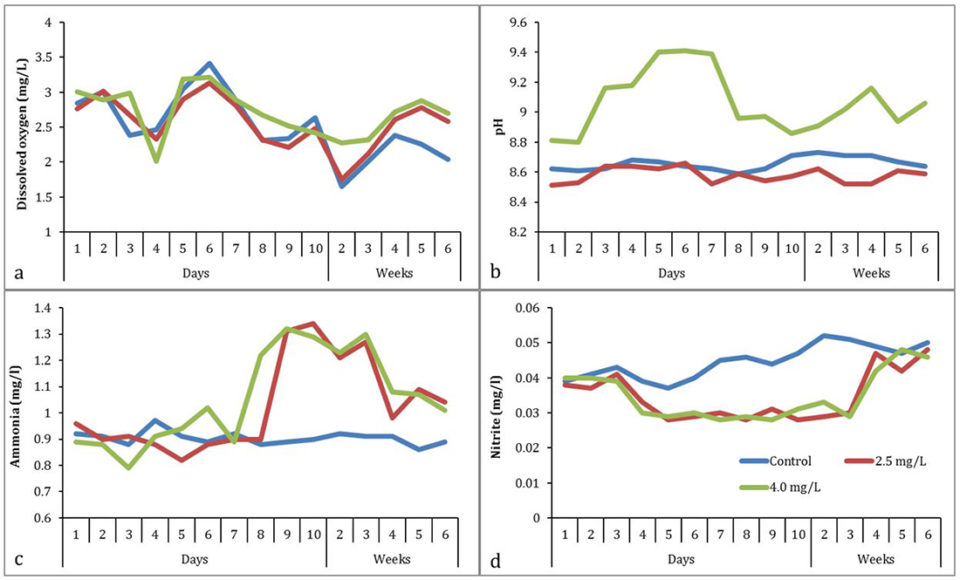

Both doses of 2.5 and 4.0 mg/L H2O2 significantly reduced total microcystins from seven and five days, respectively, until the end of the trial (Fig. 2). The added H2O2 rapidly degraded to below detectable levels after days 3 and 4, respectively (Fig. 3). The dissolved oxygen remained relatively stable over this study (Fig. 4a). The pH was lower in both H2O2 ponds but was more stable over time (Fig. 4b). There was a spike in ammonia within 2.5 and 4.0 mg/L H2O2 ponds on days 7 and 8, respectively, but these were within the tolerance of freshwater animals and decreased after week 3 (Fig. 4c). On the other hand, nitrite remained low and stable in all ponds (Fig. 4d).

Overall conclusions

Issues with extermination of cyanobacteria with traditional algaecides may include temporary deteriorations in water quality, unintended toxicity to beneficial plankton or high levels of microcystins. However, these were substantially mitigated by H2O2 at 2.5 mg/L in the form of SCP. In fact, this was slightly beneficial to zooplankton, likely due to the reemergence of eukaryotic microalgae as the cyanobacteria died. Moreover, the use of this product left no long-term traces of H2O2 in the water.

It is important to point out that, while the small-scale trial was an important step in this study, there were some discrepancies that included a concentration of 4.0 mg/L of the algaecide negatively affecting the plankton community within the ponds. Thus, caution should be used when small-scale trials are used to predict those in a large-scale commercial setting.

Overall, our results demonstrate that the granular SCP-based algaecide (PAK® 27) –corresponding to 2.5 mg/L H2O2 – can be recommended as an eco-friendly strategy to effectively remove populations of the cyanobacterium Planktothrix sp. without compromising water quality or other plankton communities.

Future research and perspectives

A limitation of this was study was not assessing the potential toxicity of H2O2 to fish. There are indications this would be safe, based on no apparent toxic effects to zooplankton at 2.5 mg/L and limited persistence in water; however, this will be tested in the future on juvenile channel catfish and largemouth bass.

This research will also extend to other cyanobacterial species as well as any potential effect this could have on compounds that cause “off-flavors” (e.g. geosmin and MIB), often a side-effect of hypereutrophic ponds that causes substantial economic losses to farmers.

Authors

-

Amit Kumar Sinha, Ph.D.

Aquaculture/Fisheries Center

University of Arkansas at Pine Bluff

1200 North University Drive

Pine Bluff, AR 71601 USA[109,111,99,46,108,105,97,109,103,64,97,117,46,97,104,110,105,115,116,105,109,97]

-

Nicholas Romano, Ph.D.

Corresponding author

Aquaculture/Fisheries Center

University of Arkansas at Pine Bluff

1200 North University Drive

Pine Bluff, AR 71601 USA[117,100,101,46,98,112,97,117,64,110,111,110,97,109,111,114]

-

Michael Eggleton, Ph.D.

Aquaculture/Fisheries Center

University of Arkansas at Pine Bluff

1200 North University Drive

Pine Bluff, AR 71601 USA -

John Howe

Aquaculture/Fisheries Center

University of Arkansas at Pine Bluff

1200 North University Drive

Pine Bluff, AR 71601 USA -

Rebecca Lochmann, Ph.D.

Aquaculture/Fisheries Center

University of Arkansas at Pine Bluff

1200 North University Drive

Pine Bluff, AR 71601 USA

Tagged With

Related Posts

Responsibility

Factors affecting efficiency of commercial fertilizers in aquaculture

Intensification of pond aquaculture involves the use of commercial fertilizers such as urea and triple superphosphate to stimulate phytoplankton blooms. There is no objective way of determining the ideal fertilization rate for an individual pond.

Health & Welfare

Phytoplankton a crucial component of aquaculture pond ecosystems

Phytoplanktonic organisms, or microalgae, are very abundant in aquaculture ponds and have critical roles in these ecosystems, significantly influencing overall pond ecology and water quality. Proper management of phytoplankton populations is essential for successful aquaculture pond production.

Aquafeeds

Gamma irradiation enhances nutritional value of animal byproducts

Gamma irradiation treatment presents a possible processing technique for reducing anti-nutrients and improving the nutritive quality of many feed ingredients.

Responsibility

Phytoplankton in aquaculture ponds: Friend or foe?

A vigorous phytoplankton bloom will support a healthy benthic community and will contribute significantly to stabilising and maintaining adequate pond water and bottom quality.