TCFFI study shows their potential to remove nitrate, phosphorus and suspended solids

Nutrients, particularly nitrogen and phosphorus, can create eutrophication problems in any watershed. Preventing water quality impairment requires controlling nutrients from both point-source and non-point source discharges.

Woodchip bioreactors are one relatively new approach that can be utilized for both applications. These denitrifying bioreactors are essentially carbon-filled trenches intended to create an environment similar to that of a nitrogen-scrubbing wetland. Within the woodchips an anoxic zone (that is, no/low oxygen) is maintained, encouraging naturally occurring bacteria to utilize available nitrate in place of oxygen, eventually respiring harmless atmospheric di-nitrogen gas.

Benefits of choosing woodchip bioreactors over other denitrification technologies include their small ecological footprint due to low/no energy requirements, enhancement of a natural treatment process, and relatively low installation and maintenance costs.

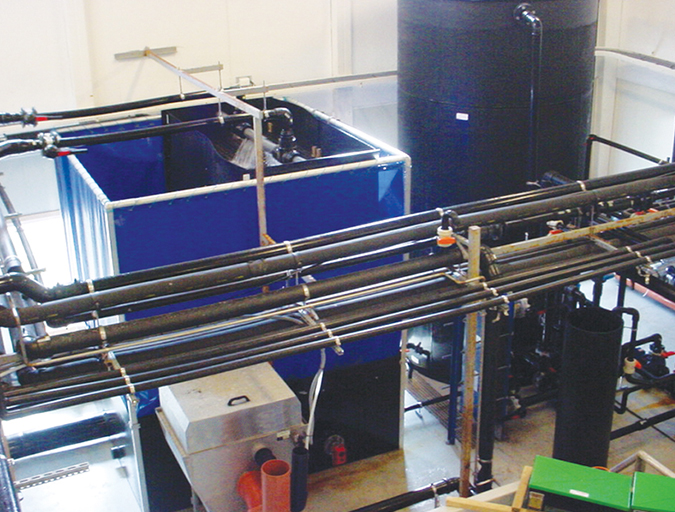

The Conservation Fund’s Freshwater Institute, located in Shepherdstown, West Va., USA, investigated the potential of woodchip bioreactors, traditionally used for non-point agricultural drainage, to remove nitrate, phosphorus and suspended solids from point source recirculating aquaculture systems’ effluent. We are grateful to and acknowledge the support by Tides Canada and the U.S. Department of Agriculture’s Agricultural Research Service (ARS) for this research.

Wood-based heterotrophic denitrifying bioreactors

An enhanced-denitrification bioreactor is a farm- or field-scale technology designed to address increasing levels of reactive nitrogen (N) in the environment. This nitrogen pollution from agricultural activities causes eutrophication, hypoxia (dead zones), and habitat degradation which results in biodiversity losses in coastal waters around the world. Over the past two decades, wood-based heterotrophic denitrifying bioreactors have been used to mitigate nonpoint source nitrogen pollution associated with agricultural activities and from point source pollution such as greenhouses. Other agricultural point sources, in particular land-based recirculating aquaculture systems (RAS), stand to benefit greatly from such relatively simple denitrification technologies.

Outflow streams from both RAS wastewater and effluent are suitable for application of this denitrification technology. When compared with agricultural field application (such as tile drainage) of wood-based denitrifying bioreactors, the treatment of RAS outflows are advantageous as tightly controlled systems prevent variable flow rates and seasonal temperature fluctuations that can affect the denitrifying bacteria’s performance.

Study setup and results

Supernatant generated from gravity thickening tanks used to dewater biosolids found in drum filter backwash and radial flow settler flushing flows was produced by water recirculating systems at the Freshwater Institute. Thus, the aquaculture effluent entering the woodchip bioreactors would have come close to or exceeded acceptable effluent discharge guidelines, with mean total suspended solids, carbonaceous biochemical oxygen demand, and nitrate nitrogen concentrations of 64, 37 and 48 mg/L, respectively, over the duration of the study.

Varying hydraulic retention times were examined to determine the most efficient woodchip bioreactor design, maximizing nitrate removal while avoiding other undesirable processes (sulfate reduction or mercury methylation).

A near optimum hydraulic retention time was approximately 24 hours for this water chemistry and temperature yielding a nitrate-nitrogen removal rate and efficiency of 18 g/(m3d) and 65 percent, respectively (Lepine et al., 2015. Journal of Environmental Quality 45(3), 813-821. doi:10.2134/jeq2015.05.0242). Shorter hydraulic retention times of 6 and 12 hours produced the highest nitrate removal rates, at up to 39 g/(m3d), but reduced nitrogen removal efficiencies and were more likely to plug (see more on plugging below).

Designs using longer hydraulic retention times maximize nitrogen removal efficiency (99 percent removal), but also result in higher amount of sulfate reduction and sulfide production under highly reduced, nitrogen-limited conditions. Note that longer hydraulic retention time also requires a larger bioreactor, but could potentially provide better treatment efficiencies and reduce the plugging potential of the woodchips. Designs using shorter hydraulic retention times (at near 6 or 12 hour), are more likely to rapidly plug the bioreactor and provide reduced treatment efficiency.

The study also found that woodchip bioreactors that remove nitrate from water can export phosphorus during the start-up phase. However, by their 100th day of operation, dissolved phosphorus loss had transitioned to phosphorus removal from the wastewater. Over longer-term, woodchip bioreactors showed 15 to 54 percent total phosphorus removal from aquaculture wastewater (Sharrer et al, 2016. Ecological Engineering 93, 135-143).

Woodchip bioreactors also removed over 90 percent of the suspended solids throughout the 267-day study; solids removal occurred primarily at the bioreactor inlet. However, this research also suggests that the high levels of suspended solids in some aquaculture effluent could create plugging and hydraulic problems in woodchip bioreactors operated over either extended periods or shorter hydraulic retention times (Christianson et al., 2016. Water Research 105, 147-156. http://dx.doi.org/10.1016/j.watres.2016.08.067).

Perspectives

Woodchip bioreactors can effectively remove nitrate, phosphorus, and total suspended solids from aquaculture waste waters. Research findings will help calibrate woodchip bioreactor design models specifically for recirculated aquaculture wastewater. In addition, woodchip bioreactor denitrification treatment of the relatively organic-rich aquaculture wastewater is a new and useful application of this effective water treatment technology to protect against water pollution.

To further extend this work, a follow-up study has begun to test improved flow-distribution manifolds at the inlet, ideally reducing plugging and extending the operating life of woodchip bioreactors without compromising nitrogen and solids removal efficiency. Preliminary study has also indicated along with suspended solids removal, bioreactors may reduce both total and fecal coliforms further improving aquaculture effluent’s water quality.

Authors

-

Christine Lepine

Research Technician

The Conservation Fund Freshwater Institute

1098 Turner Road

Shepherdstown, WV 25443 USA[103,114,111,46,100,110,117,102,110,111,105,116,97,118,114,101,115,110,111,99,64,101,110,105,112,101,108,46,99]

-

Laura E. Christianson, Ph.D.

Assistant Professor of Water Quality

Department of Crop Sciences

University of Illinois

S322 Turner Hall

1102 S. Goodwin Ave.

Urbana, IL, 61801 USA

http://draindrop.cropsci.illinois.edu[117,100,101,46,115,105,111,110,105,108,108,105,64,115,105,114,104,67,69,76]

-

Kata Sharrer

Engineering Technician

The Conservation Fund Freshwater Institute

1098 Turner Road

Shepherdstown, WV 25443 USA[103,114,111,46,101,116,117,116,105,116,115,110,105,114,101,116,97,119,104,115,101,114,102,64,114,101,114,114,97,104,115,46,107]

-

Steven Summerfelt, Ph.D., PE

Director, Aquaculture Systems Research

The Conservation Fund Freshwater Institute

1098 Turner Road

Shepherdstown, WV 25443 USA

www.conservationfund.org[103,114,111,46,101,116,117,116,105,116,115,110,105,114,101,116,97,119,104,115,101,114,102,64,116,108,101,102,114,101,109,109,117,115,46,115]

Tagged With

Related Posts

Innovation & Investment

Estimating biofilter size for RAS systems

Controlling total ammonia-nitrogen (TAN) concentrations is the primary concern when sizing a biofilter for use in a recirculating aquaculture system. Sizing decisions are best based on previous experience with a given biofilter media in a specific biofilter configuration.

Health & Welfare

Novel air-based system transfers large salmon during harvest

To evaluate the application of an air pressure-based transport method within a recirculating aquaculture system, the authors performed testing with harvest-size salmon at The Conservation Fund Freshwater Institute.

Innovation & Investment

Matorka aims to unearth innovation with Arctic charr

A new and ambitious Iceland company is about to construct what it claims will be the world’s largest land-based salmonid farm. What sets Matorka’s Arctic char farm apart is its ability to tap into natural resources unique to the island nation.

Intelligence

Walleye and saugeye growing successfully indoors

Past and ongoing studies at the UWSP Northern Aquaculture Demonstration Facility (UWSP-NADF) have shown that walleye and hybrid walleye can be successfully raised indoors using early advanced spawning, incubation and rearing techniques. Marketing studies indicate good aquaculture potential and high demand.